Pharmaceutical Packaging Trends – Innovations Shaping the Future of Medicine

Pharmaceutical packaging practices have evolved drastically over the years, changing to fit the needs of the pharmaceutical industry and its customers. In ancient times, medicines were kept in whatever was most readily available, often clay pots. For liquid medicines, however, animal bladders were sometimes used because they could contain liquids and keep them from seeping out or evaporating. Some later cultures used silk pouches for herbs or other medicinal substances, and glass became a popular way to store medicines because it could protect against an array of outside elements.

Today, the pharmaceutical market has found numerous new ways to package medicines, including plastic packaging, child-resistant packaging, packaging design, and more. While each packaging option has its own pros and cons, pharmaceutical packaging trends are ever-changing in an effort to find the most efficient and helpful way to get medicines into the hands of those who need them.

Cutting-Edge Materials in Pharmaceutical Packaging

Various new materials are being used to transport medicinal orders, some of which have never been used for such things before. Some of these include:

Smart Packaging

Smart packaging is a broad term used to define packaging that uses technology to function. Some smart pharmaceutical packaging is used to eliminate moisture, extend shelf life, identify and track packages, connect to a patient’s electronic devices to provide information, and offer accessibility to patients needing assistance opening their packages.

This technology functions through sensors or electronic components that provide data and can help inventory management. Smart packaging is a helpful innovation because it can be personalized to fit the needs of each patient.

Tamper-Evident Packaging

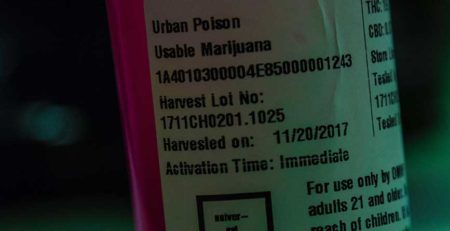

This type of packaging was created to decrease the amount of counterfeit drugs and tampering with medications that are shipped or mailed. It can often be difficult to discern whether a medication has been altered, and any alteration could result in serious injury to the patient, highlighting the importance of innovative packaging design in the pharmaceutical industry.

Tamper-evident packaging intends that recipients see if their package has been altered clearly. This is done through seals, labels, and closures that clearly reveal if they have been broken or opened. This innovative packaging is essential as the rise of pharmaceutical tampering and counterfeiting continues.

Sustainable Packaging

The amount of waste produced by global pharmaceutical industries and humanity continues to rise. In light of this, many companies that mass-produce products to ship and mail have begun to explore the possibilities of sustainable packaging solutions. This includes biodegradable and recyclable packaging materials. Sustainable pharmaceutical packaging helps eliminate waste and encourages a culture that does so.

Interactive Pharmaceutical Packaging

A tiny label printed on the side of a medicine bottle only sometimes provides all of the information that a patient may need, especially information that fits their particular circumstance. For this reason, interactive pharmaceutical packaging was created.

This type of packaging includes QR codes, augmented reality (AR), and near-field communication (NFC) technologies. These innovations allow the patient to access online information, including instructions on how much medicine to take, when to take it, how far apart doses should be, and other helpful information relating to the medicine. With this technology, patients have access to all of the information they need at their fingertips.

Sustainable Practices in Pharmaceutical Packaging

Eco-friendly packaging has become popular in today’s society, regardless of the production field, signaling a shift towards sustainability in the packaging industry. Sustainable packaging takes many forms, focusing on transporting packages in an eco-friendly way and using biodegradable, recyclable, or compostable materials. Some examples of sustainable packaging practices include:

- Minimizing waste by using packaging products that fit the materials being packaged.

- Using materials that are biodegradable, recyclable, or compostable rather than plastics and other materials that are harmful to the environment or cannot be reused.

- Being mindful of the modes of transportation that are used to deliver products. Leaving behind the smallest carbon footprint possible is always the goal in the pharmaceutical packaging market to minimize environmental impact.

Patient compliance packaging solutions that are also eco-friendly commonly include substituting:

- Plastic tape for paper tape to keep a package tightly secured.

- Films for foams when trying to keep a product secure in its packaging.

- Vegan thermal liners for temperature control.

Smart Packaging Technologies

Smart packaging technologies are becoming increasingly popular because they provide more security and information to each patient. The top three forms of smart packaging advanced technologies are:

- Smart labels: Smart labels use innovative technology to trace and track the packages they are applied to. For pharmaceutical companies, this allows them to track their packages from the moment they are shipped from the factory to wherever they end up, including hospitals, the homes of individual patients, or anywhere else. This information can be useful when recorded because it can help pharmaceutical companies increase their efficiency in delivery.

- QR codes: QR codes offer accessibility to online information. For patients receiving pharmaceutical products, a QR code may contain information relating to dosages, ingredients, and more. Patients can also use QR codes to set reminders on their phones if the product they are receiving is a medicine that is taken recurrently. The QR code can help them set a reminder on their device so they do not forget to take their medicine.

- Near-field communication technology: NFC, or near-field communication technology, allows devices close to one another to communicate and share information. In the world of pharma packaging, this can take many forms, including medication adherence, temperature information, protection from tampering and counterfeiting, addressing sustainability, patient safety, and more.

Regulatory Impacts on Pharmaceutical Packaging

The regulatory impact on packaging pharmaceutics is high, as it should be. Global pharmaceutical packing procedures must comply with the World Health Organization’s standards.

These standards cover how pharmaceutical products are to be labeled, how repackaging should occur if needed, the types of admissible materials, and more. Compliance with regulations such as these is one of the driving forces behind the numerous innovations in pharmaceutical packaging. Each step of the packaging process influences the integrity of the packaging, making each step critically important.

The Future of Pharmaceutical Packaging

The future of pharmaceutical packaging trends will likely involve finding new eco-friendly packaging materials with increasing safety innovations and balancing environmental impact with patient safety. With ever-evolving technologies such as artificial intelligence, it will become easier to design personalized packaging for each patient and more efficient for each company to produce. As packaging needs and technological advancement trends change, it’s crucial to maintain compliance and stay up-to-date on the latest innovations.

Royal Label is one of the leading companies in printed pharmaceutical labels. We understand their role in enhancing medication safety and supply chain integrity in the pharmaceutical packaging industry. We ensure our customers comply with regulatory standards and provide the highest quality products. Contact Royal Label today to learn how to keep up in an ever-changing world with professional, personalized labeling services for your pharmaceutical company.