Navigating GMP Drug Labeling Requirements: Guidelines for Medical and Pharmaceutical Labeling

Regarding pharmaceuticals and medical products, compliance with Good Manufacturing Practice (GMP) regulations is not just a regulatory necessity; it’s a cornerstone of consumer safety and trust. These guidelines govern the entire lifecycle of pharmaceutical products, from research and development to manufacturing and labeling. In an industry where precision and accuracy are paramount, GMP labeling requirements provide the framework that ensures pharmaceutical and medical drug products meet the highest quality standards.

The meticulous adherence to GMP packaging regulations is a requirement and a testament to an organization’s commitment to producing safe and effective healthcare solutions. From the inception of a pharmaceutical product through its journey to the patient, every step is guided by GMP principles, guaranteeing that the label on a medication bottle or medical device is not just a piece of information but a promise of trust and well-being.

This guide will navigate the intricate world of GMP compliance concerning medical, pharmaceutical, and biological product labeling, providing insights and solutions for maintaining the highest consumer safety standards and regulatory compliance.

Understanding the Core Elements of GMP Labeling

Mandatory Label Information

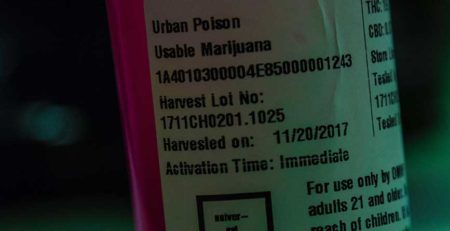

Under GMP labeling regulations, product labels are crucial in ensuring consumer safety. These labels must include vital information, including product names, strengths, intended use, dosage, and potential side effects. The pharmaceutical sector, in particular, places a strong emphasis on accurate ingredient listings and precise dosage information, recognizing that even the slightest error in this information can have significant consequences for patient well-being.

Industry-Specific Requirements

GMP drug labeling requirements extend beyond pharmaceuticals to cover various industries, including food, cosmetics, and medical devices. Each sector has its own distinct labeling prerequisites. In the pharmaceutical field, these specifications are particularly rigorous. They encompass active ingredient details, dosage forms, and therapeutic indications. This level of detail is not just a regulatory necessity; it’s a vital aspect of ensuring that patients receive the proper medications correctly, bolstering their health and well-being. Understanding these industry-specific demands is fundamental to GMP compliance in the pharmaceutical and medical sectors.

Compliance with GMP Labeling Regulations

Ensuring Compliance

To meet GMP packaging requirements, pharmaceutical manufacturers must meticulously establish robust processes and procedures within their organizations. These processes encompass everything from label design and printing to quality control measures. Maintaining proper documentation and comprehensive record-keeping is vital as a testament to the commitment to GMP compliance. This simplifies regulatory inspections and ensures that every label adheres to the highest standards. Regular audits and inspections are integral to this process, helping to guarantee that labeling practices remain consistent with GMP standards.

Consequences of Non-Compliant Labeling

The repercussions of non-compliant labeling extend far beyond the regulatory arena. Non-compliance can lead to significant penalties and, more importantly, jeopardize the reputation of a pharmaceutical company. Strict adherence to GMP guidelines is not just a legal requirement; it is the only way to guarantee consumer safety and unwavering regulatory compliance. It reflects an organization’s commitment to the safety of consumers and the reliability of its products. By staying compliant, pharmaceutical companies demonstrate their commitment to producing products of the highest quality that benefit both patient well-being and the organization’s reputation in the industry.

Label Design and Layout Considerations

Clear and Legible Labels

Central to GMP labeling is the need for labels to be unequivocally clear and effortlessly legible. Labels should be designed so that consumers and healthcare professionals can easily comprehend the information presented. Achieving this objective involves meticulous considerations, encompassing font size, the precise placement of mandatory information, and the strategic use of appropriate colors and graphics to enhance visual clarity. By adhering to these principles, proper GMP labeling ensures that labels are not just pieces of paper but vital sources of information that all stakeholders can easily understand.

Labeling for Special Circumstances

Special Claims and International Distribution

In a dynamic marketplace, certain pharmaceutical products carry distinct claims, such as “organic” or “natural.” These special claims necessitate additional labeling requirements, ensuring transparency and accuracy in product representation. For pharmaceuticals intended for international distribution, the complexity multiplies. Multilingual labels are often a requisite to facilitate comprehension across diverse markets. These intricate label considerations underscore the importance of adaptability and precision in GMP labeling, enabling pharmaceutical companies to navigate an ever-expanding global landscape.

Allergen Labeling

In a world where the number of individuals with allergies continues to grow, the importance of proper allergen labeling cannot be overstated. The labeling requirements for allergens and associated warnings are fundamental to safeguarding the health and well-being of potentially vulnerable consumers. By implementing precise allergen labeling practices, pharmaceutical manufacturers prioritize consumer safety, ensuring patients can confidently use and benefit from their products without concerns about allergenic reactions.

Implementing GMP Labeling Requirements in Your Organization

Best Practices

To seamlessly implement GMP labeling requirements, pharmaceutical manufacturers must establish adequate and robust processes and procedures within their organizations. These encompass every aspect of labeling, from the design phase to printing and quality control. In pursuit of optimal results, pharmaceutical companies may find value in partnering with a trusted printer. With specialized expertise in producing labels that adhere to GMP standards, your printing partner will become a valuable ally in maintaining uncompromising labeling quality.

Employee Training

Ensuring that employees involved in labeling processes receive comprehensive training and education is a fundamental component of GMP compliance. Individuals who execute these processes of product labeling must possess a deep understanding of GMP guidelines and how they apply to their roles. Properly trained employees are an essential asset in the quest for label accuracy and safety, ultimately contributing to a higher standard of pharmaceutical quality.

Regular Audits and Inspections

Achieving and maintaining GMP labeling compliance is an ongoing commitment. Regular audits and inspections are how this commitment is put into action. They are a proactive safeguard to ensure that labeling practices remain consistent with GMP standards. These periodic checks are not merely regulatory obligations but essential steps to safeguard consumer safety. By conducting regular audits and inspections, pharmaceutical companies demonstrate a commitment to the well-being of those who rely on their products, reinforcing their reputation as providers of trusted healthcare solutions.

Stay Compliant With GMP Regulations When You Partner With Royal Label

GMP labeling requirements are the bedrock of pharmaceutical and medical product quality and safety. They are not merely guidelines; they are a commitment to the well-being of consumers and the success of your organization. Partner with a trusted printing company like Royal Label to ensure your organization complies with all GMP regulations. For inquiries regarding GMP-compliant labeling or to learn more about our printing services, please contact us today.